| Attaching Machines |

|

|

Model E5 2-Hopper

YKK Snap Fasteners America's Model E5 Rotary Hopper machine works quickly and efficiently. The Specially designed hopper drums eliminate product damage while allowing controlled and consistent feeding of small delicate components making it the perfect attaching machine for the Snapet.

YKK Snap Fasteners America emphasizes operator safety and comfort with a variety of standard features including fully enclosed pinch points, easy maintenance access, finger safety guards, clear-view hopper bins, and ergonomic stands.

|

|

Model E6 4-Hopper

The Model E6 4-Hopper Machine has all the features of the Model E5 with the added benefit of feeding four Snapet components on one machine - one machine is all that is required to make both socket and stud attachments.

Enhanced with a computer controlled sequence counter, programming this machine is as simple as pressing a button to change the counter and sequence of each attachment. This gives the operator the option of choosing the sequence by which the components are fed allowing for greater production flexibility. The operator can continuously apply the components while the machine alternates the product combinations following a preset program.

|

|

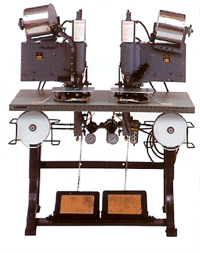

Hook & Eye Equipment

Hook and Eye attaching machines are air operated and components are hopper-fed. The simplicity of this machine's design means fewer moving parts and less maintenance.

An optional stay-feed device positions, cuts, and attaches a reinforcement swatch of fabric with each closure. Other options are available for gauging single or double-spaced attachments.

Hook and Eye equipment can be mounted on a table stands as singles or in tandem sets (as shown). Custom set-ups are available for special applications.

|

|

Model II Attaching Machine

The air-operated Model II attaching machine is safe, cost-effective and durable. It offers high-speed attaching capabilities for buttons, snaps, rivets and burrs. With its slim profile, it takes up less floor space than traditional machines. All operating parts are guarded; however, they are easily accessible for routine maintenance. The feeding system, featuring a non-rotating hopper, virtually eliminates marring and scratching of products. An optional reserve hopper is available to increase product capacity and operator productivity.

Model II machines can be activated either by a finger or foot switch to accommodate stand-up or sit-down operations. Model II machines come standard on adjustable pedestal stands or can be mounted in tandem on tables. Other options include spacing gauges for precise location of each attachment, spotter light locations and auto-feed reinforcement tape.

|

|

"FP" Series

FP Series presses are available in single (FP1) and Double (FP2) head versions, and are capable of attaching almost any fastener product in the industry. The FP presses can be utilized to attach snaps, buttons, rivets and burrs, eyelets, grommets and a host of other products. Secure attachments are ensured through adjustable die settings which are achieved using the easy access thumb screw on the bottom of the die-holders.

FP footpresses are also available with air assisted power packs to add consistency to each attachment.

|